In the realm of industrial heat trade structures, the selection of equipment significantly impacts efficiency, overall performance, and cost-effectiveness. Among the numerous forms of warmth exchangers to be had, shell and tube heat exchangers and double pipe heat exchangers are popular alternatives. However, on the subject of massive-scale packages, shell and tube heat exchangers turn out to be the advanced choice. This weblog explores the motives behind this desire, highlighting the benefits and packages of each type.

Understanding Heat Exchangers

Heat exchangers are vital additives in diverse industries, facilitating the switch of heat among two or greater fluids. The preference between exclusive forms of heat exchangers often relies upon on elements along with area, temperature, pressure, and fluid characteristics.

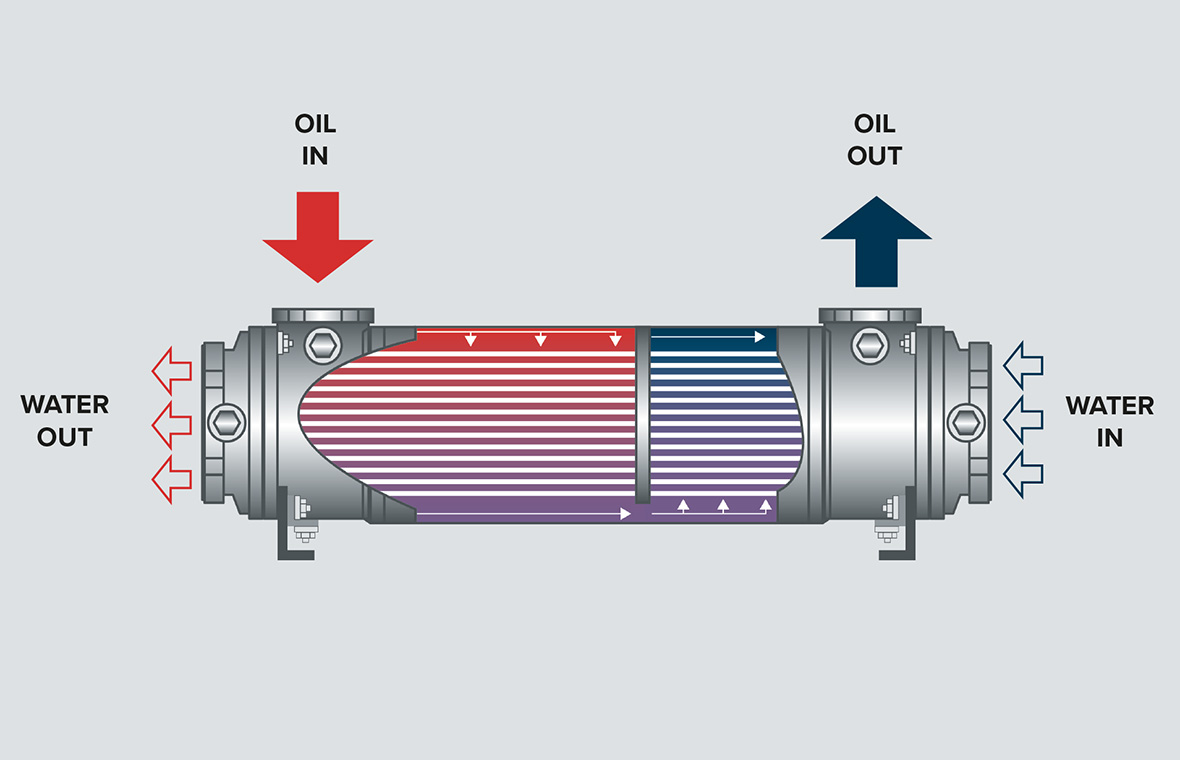

Shell and Tube Heat Exchangers

shell and tube heat exchanger encompass a chain of tubes, one set sporting the new fluid and the alternative wearing the bloodless fluid. The tubes are enclosed within a bigger shell, taking into account green warmness transfer between the fluids. This design permits excessive warmth switch coefficients and is appropriate for massive capacities.

Double Pipe Heat Exchangers

On the opposite hand, double pipe heat exchangers include one pipe inside any other, wherein one fluid flows thru the internal pipe and the alternative fluid flows in the annular area between the two pipes. While simpler in layout, this sort of warmth exchanger is generally more acceptable for smaller packages.

Advantages of Shell and Tube Heat Exchangers

1. High Heat Transfer Efficiency

One of the number one benefits of shell and tube warmth exchangers is their excessive heat transfer efficiency. The layout allows for extra surface location touch between the fluids, enhancing the overall heat alternate procedure. This function is specifically critical in big-scale applications, in which green warmth switch can cause good sized energy financial savings.

2. Robust Design for High Pressure and Temperature

Shell and tube heat exchangers are constructed to resist high pressure and temperature conditions, making them perfect for annoying industrial environments. The sturdy creation enables them to operate efficiently in various packages, consisting of electricity technology, chemical processing, and oil and gasoline sectors.

3. Versatility in Design

These warmth exchangers can be designed to house multiple tube configurations and materials, permitting for personalisation based totally on precise utility requirements. Industries can effortlessly modify the variety of tubes and the format to optimize performance for their desires.

4. Easy Maintenance

Maintenance is a critical element of any warmness exchanger machine. Shell and tube warmness exchangers provide less difficult access to character tubes, facilitating cleansing and preservation. This ease of maintenance minimizes downtime, making sure that massive-scale operations keep to run smoothly.

5. Cost-Effective for Large Capacities

While the preliminary investment in shell and tube warmness exchangers can be higher than that of double pipe heat exchangers, they end up extra cost-powerful in large-scale packages. The efficiency and durability of these exchangers cause lower operational fees and decreased electricity intake over the years.

Limitations of Double Pipe Heat Exchangers

1. Limited Heat Transfer Surface Area

Double pipe heat exchangers have a extra confined floor vicinity for heat switch in comparison to shell and tube warmness exchangers. This hindrance can reduce efficiency, particularly in huge-scale applications where maximizing heat trade is crucial.

2. Lower Capacity

The design of double pipe heat exchanger restricts their ability, making them extra suitable for smaller programs. In assessment, shell and tube warmness exchangers can handle large volumes of fluid, making them a better preference for industries with high thermal needs.

3. Complexity in Scaling Up

Scaling up a double pipe warmth exchanger to satisfy the wishes of larger applications may be hard. In many instances, multiple gadgets can be required, increasing set up complexity and fees. On the alternative hand, shell and tube heat exchangers may be designed for large capacities with out tremendous modifications.

Applications of Shell and Tube Heat Exchangers

Given their advantages, shell and tube warmth exchangers are broadly utilized in various big-scale applications:

1. Power Generation

In energy vegetation, shell and tube heat exchangers are used for cooling methods and heat healing. They help keep ultimate temperatures in generators and other crucial gadget, making sure green electricity manufacturing.

2. Chemical Processing

The chemical enterprise is predicated closely on shell and tube warmness exchangers for heating and cooling tactics. These exchangers can manage corrosive fluids and high temperatures, making them appropriate for various chemical reactions.

3. Oil and Gas Industry

In the oil and gas region, shell and tube warmness exchangers are used for diverse packages, such as crude oil heating and gas cooling. Their strong layout lets in them to face up to harsh conditions and make certain green heat switch.

4. HVAC Systems

Heating, air flow, and air con (HVAC) systems regularly make use of shell and tube heat exchangers for powerful temperature regulation in huge business and commercial homes. Their performance helps keep snug indoor environments.

5. Food and Beverage Industry

In the food and beverage industry, keeping safe temperatures in the course of processing is essential. Shell and tube warmness exchangers are employed for cooling and heating packages, ensuring product quality and safety.

Conclusion

When it comes to large-scale programs, shell and tube warmness exchangers surely outperform double pipe heat exchangers. Their advanced warmth switch performance, strong layout, versatility, and ease of upkeep lead them to the favored preference in various industries. While double pipe heat exchangers may be suitable for smaller programs, the demands of big-scale operations require the skills of shell and tube heat exchangers.

Investing in shell and tube warmness exchangers isn't just about assembly present day needs; it is a strategic decision for destiny increase and efficiency. As industries maintain to adapt, embracing advanced warmness alternate technology can be vital in optimizing overall performance and reducing operational prices. The desire is apparent: for huge programs, shell and tube warmness exchangers are the first-rate solution.